Why Bend Radius is Important for Hydraulic Hose Installation

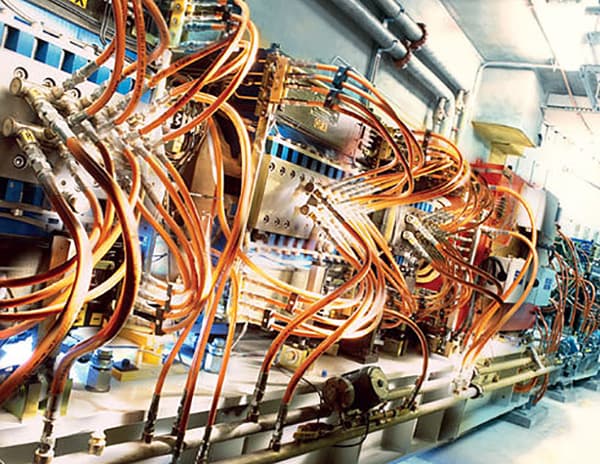

Image Description: Hydraulic Assembly

The hydraulic system can be stationary or have moving parts like cylinders, actuators, racks, and pinion drives that may extend or retract hoses. Additionally, hoses may need to be bent to fit with various components in hydraulic hose installations, like pumps, coolers, and filters.

Observe caution during installation as it may lead to drastic consequences if attention isn’t paid to the minimum bend radius when designing hydraulic hose installations. Here, we look at what a minimum bend radius is and why it is important in many hydraulic systems.

What is Minimum Bend Radius?

The flexibility of a hydraulic hose depends on the number of reinforcement layers it has and the thickness of the outer cover. Manufacturers specify the minimum bend radius for their hoses which is the minimum radius a hydraulic hose can be looped into without sustaining damage to the inner layers.

To ensure you follow the manufacturer’s guidelines, measure the bend radius of every arc in a hydraulic hose assembly when it is fitted onto your hydraulic system. As per the formula = sφ, you use the length of the arc (s) and the angle the loop sweeps (φ) to find the radius. If it is lower than the minimum bend radius, you’ll need to make adjustments to the hose assembly.

Common Misconceptions

Rookie engineers often make the mistake of ordering higher bend radius hoses, thinking that the relationship between flexibility and bend radius is proportional. However, that’s not the case. The lower the bend radius, the smaller diameter a hose can be looped into.

Additionally, you cannot tell the bend radius of a hose just by looking at it because the property varies depending on the construction of the hose. It has more to do with how the layers of the hydraulic hose are constructed and how many of them are present. Braided mesh hoses are generally more flexible than spiral wound hoses with the same number of layers. That’s because the thinner wires in a mesh braid allow room for movement, increasing flexibility. Hence, two hydraulic hoses with the same thickness don't need to have the same minimum bend radius as well.

Why is Bend Radius Important to Consider?

Bend radius is often overlooked when hydraulic hose installations are being assembled. Time constraints, budget issues, and improper knowledge of hydraulic hoses are some of the factors that contribute to this oversight. However, this small oversight can lead to major safety issues if left unattended. Moreover, it may become costly to repair the damage sustained instead of investing in the correct hose in the first place.

Prevent Deformation

Force may be required to bend a hydraulic hose beyond its minimum bend radius to bend it more; however, this can cause the different materials inside the reinforcement layer to deform beyond a level of recovery. Typically, this layer is made of steel or polymer wire braids whose wires can damage and decrease the strength of the hydraulic hose. Over time, with intense flexing and jittering of the hose due to operating conditions, this layer can break and cause leakages in the pipe.

Prevent Inefficiencies

Hydraulic hose installations are part of a system where the pressure constantly changes as it moves from one component to another. This is due to the transfer of energy when changes in pressure drive useful work out of the system; hence, depending on the load on the system, more work will be required from its driving mechanism. If the pressure becomes too high and there’s an excessive bend in one of the hoses, it may cause a constriction in one of the lines requiring more work from the system and introducing inefficiencies.

Prevent Ruptures

Following from above, if the bend is excessive, the hose is weakened, and a constriction is present, hydraulic oil may build up to such excessive levels that the hydraulic hose may no longer sustain. This may lead to a rupture in the hydraulic hose and then becomes a safety issue.

Bottom Line

Considering the convoluted nature of hydraulic installations, it is understandable that some hose assemblies may get overlooked during installation. However, regular machine checks can identify which hose assembly is not up to code and can be replaced when a suitable part arrives. Till then, you might want to look into adjusting the length, fittings, and route of the hose assembly to mitigate the effects of exceeding the minimum bend radius. It will not only ensure safety for operators and maintenance teams but also improve the performance and longevity of the hydraulic installation.