What is a JIC Fitting?

Image Title: JIC fitting

The Difficulty with finding the right fitting for your fuel and hydraulic system is that the industry does not conform to one particular standard and varies based on your geographical location. JIC fittings are commonly used for most fluid conveyance systems based on the SAE J514 and MIL-DTL-18866 standards; however, AN (Army-Navy), JIS, Komatsu are also seen within tooling and machinery.

It is crucial to know the differences between the different standards when purchasing fittings for hydraulic assemblies as they are manufactured to specific dimensions and tolerances. Failure to do so may result in the fitting having a loose connection, leading to leaks and hydraulic failure in your lines or hoses.

Difference in Standards

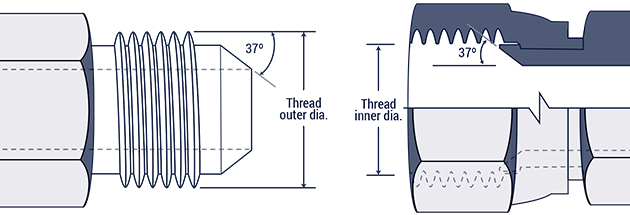

The commonality between all these fittings is that they define how a component joins and seals to other hydraulic components like their female counterparts, pipes, hoses, and valve blocks. The sealing mechanism depends on the metal-to-metal contact achieved when two compatible fittings are linked.

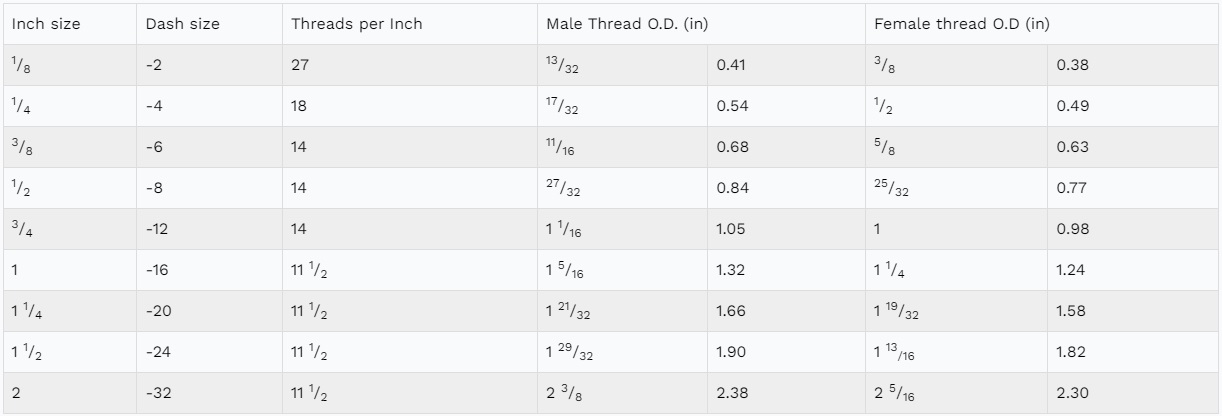

Each standard is defined by the internal diameter, thread sizing dimensions of the adapter, the flare angle on their nose, and whether the threads run parallel or taper.

AN vs JIC:

The only difference between AN and JIC fittings is that AN fittings are manufactured as per more stringent tolerances for military applications.JIS and Komatsu vs JIC:

JIS and Komatsu are similar in their appearance to JIC fittings; however, they have a 30° flare on their fittings as opposed to the 37° flare in JIC fittings. Additionally, JIS conforms to the BSP (British Standard Pipe) thread sizing and Komatsu to the millimeter.SAE vs JIC:

The thread sizing in JIC fittings are based on SAE parallel running thread sizing. It is for this reason why SAE 45° flare thread fittings can thread onto JIC fittings; however, caution must be taken as they do not have the same flare angle for seating.Advantages of Using JIC Fittings

JIC fittings are one of the most adaptable types of fittings in the market. It is for this reason they are most commonly used in the hydraulic and automotive sectors. The market displays a wide variety of multi-standard fitting interconnections such as JIC unions, JIC to pipe, or JIC to the bulkhead. Additionally, variations within these products can also be found, including elbows, reducers, expanders, straight sections, swivels, tees, crosses, and many more.

The volume and variety of material available in stock with most vendors ensure that you’re never short on inventory. Hence, you can be sure that no bottlenecks present themselves during maintenance operations. Common materials used to make JIC fittings like carbon and stainless steel, brass, and nickel-copper alloys, enable their use for custom applications where cost, resistance, temperature rating, and pressure rating are a factor.

Shortcomings of JIC Fittings

With advancements in heavy machinery, more and more applications are coming forward that require tighter seals. Unfortunately, JIC fittings are not as capable of sealing high-pressure fluids unless the standard for manufacturing conforms to stricter tolerances for flare seat faces. O-ring sealed fittings are better suited for these applications as the compression of the O-ring enables them to withstand higher pressures.