Differences and Similarities Between JIC and NPT Fittings

Image Description: JIC and NPTF Drawings

Looking for hydraulic components for hose assemblies and adapters can become a tedious task if you don’t have some level of basic understanding of them. Though hydraulic industries span across different regions of the world, they don’t conform to one unified standard.

It is essential to know these differences as the components manufactured under these standards may not be interchangeable. Selecting the wrong fitting for the job may result in thread wear, leaks, and improper connections. Here we look at the two most common types of fittings, NPT and JIC fittings, and identify their similarities and differences.

Standards

JIC fittings and adapters are based on the SAE J514 and MIL-DTL-18866 standards, whereas NPT fittings’ guidelines are outlined in the AMSE B1.20.1 standards. Both standards outline the characteristics, tolerances, and sizing variations for their respective components.

JIC fittings are often mistaken for other standards like SAE, AN, JIS, and Komatsu; however, subtle differences between them don’t make them interchangeable for use. We’ll get into these differences later on when we look at their characteristics and construction.

Threads

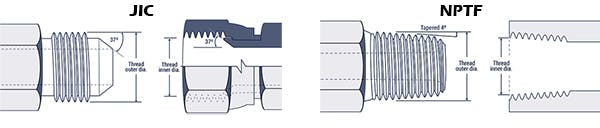

NPT, or National Pipe Tapered, gives you an indication of the kind of threads you can expect from these fittings. The threads are tapered, meaning they run at an angle of 1O 47’ (measured from the center axis of the NPT fitting). On the other hand, threads on JIC fittings run parallel to each other across the axis of the fitting.

NPT threads have flat crests and troughs, containing a 60O angle between each successive thread. JIC thread guidelines are identical to the ones outlined in the SAE – J512 standard. They can come in coarse, fine, or extra-fine thread sizes, each representing the thread count and diameters for the threads on their relevant male and female parts.

It may be possible to thread similarly sized male NPT fittings onto female JIC fittings; however, the reverse case is not possible. This practice should not be followed as the taper on male NPT fittings means that deeper threads will not interlock properly.

Flare

Both NPT and JIC fittings are machined with tapered ends. This increases the surface area of contact between the seats on interlocking parts and serves to form a tight seal between the two. However, their flare angle differs. JIC fittings come with a 37O flare angle, while the NPT fittings rely on just their tapered threads for sealing. As a result, JIC fittings offer better sealing capabilities and can withstand higher working pressures.

Other standards like Komatsu also offer flared fittings, but they also have different flare angles (30O). Also, as mentioned earlier, JIC thread sizing is identical to the SAE – J512 standard, but they differ in their flare angles and therefore are not interchangeable.

Which One Should You Use?

NPT fittings have been around for a while and come in many types, shapes, and sizes. However, the standard hasn’t evolved much since it was outlined. The ubiquity of parts may make it much more feasible for use in hydraulic systems, but its sealing properties are much to be desired when considering high-pressure applications. Hence, you may need to consider your working conditions before choosing NPT or JIC fittings.