Key Characteristics and Functions of Back Ferrules

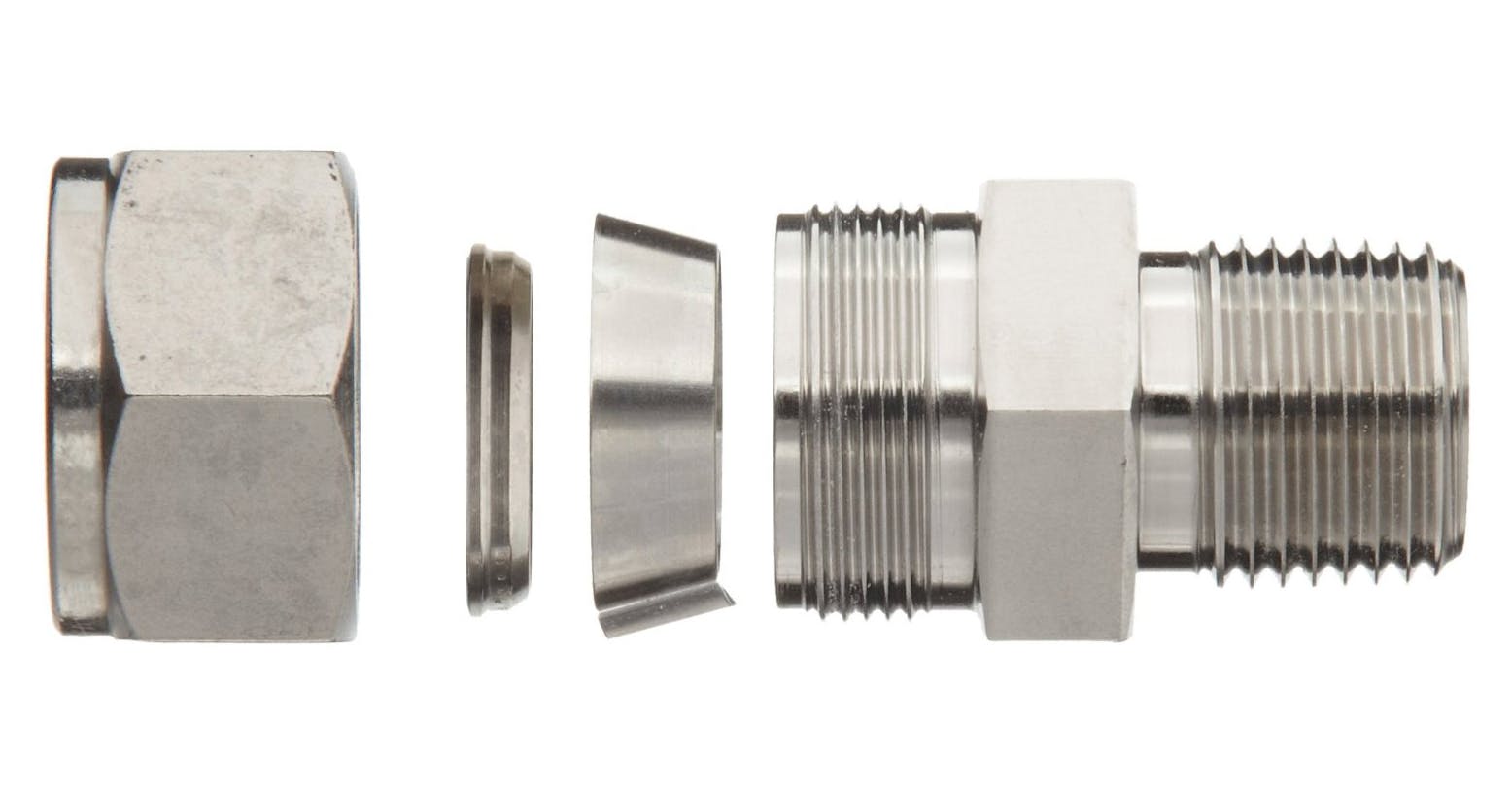

Image Description: An image showing Titan Stainless Steel Dual Ferrule Fitting

In piping and tubing-based systems, a ferrule is a small component used to seal a compression fitting assembly. Such compression fittings are necessary elements in a large variety of tubing-based applications, including plumbing, gas lines, medical devices, chromatography, and inkjet printing.

Compression fittings or tube fittings are made using three basic components: a compression nut/screw, ferrules, and a compression fitting body for all these applications. Through radial compression, a leak-tight seal is created between the tubing, ferrule, and fitting.

This brief article will outline the key characteristics and functions of ferrules for tube fittings, specifically back ferrules. By the end, you will have a better idea of various types of ferrules' design features and functions. So let’s take a closer look!

Key Characteristics of Ferrules

Ferrules are designed using a large variety of materials, including stainless steel and graphite. However, most ferrules for tube fittings are manufactured using metals as they are the most stable over a wide range of temperatures and fluid pressures.

Furthermore, there are two key characteristics to look out for when choosing ferrules for tube fittings. These characteristics will also determine the most appropriate function for the ferrule in question.

Ferrule Shape

The reliability of a compression seal depends on the shape of the ferrule and the mating angle of the fitting body. As the nut is tightened, axial alignment between the ferrule and the tube must be maintained, and it is the relative angles of the fitting body and ferrule that determine this.

Furthermore, another key characteristic of the ferrule is the sharpness of its forward edge. The degree of this sharpness will determine the uniformity of the “line contact” compression around the circumference of the ferrule, thereby ensuring a reliable seal.

Single Ferrules vs. Double Ferrules

To minimize the number of components, most tube fittings make use of a single ferrule. Single ferrule designs tend to work reliably when manufactured from soft materials like plastic and brass. The angled front end of the ferrule compresses into the fitting body and grips the tubing.

When using harder materials such as stainless steel, the rotation from tightening the nut can cause asymmetrical compression of the ferrule. Over time, the uneven transfer of torque can cause leaks. In such a case, double ferrules are used to solve this issue.

Double ferrules come with a front ferrule that compresses into the fitting body and a smaller, freely rotating back ferrule that can easily decouple the nut from the front ferrule. The chemically hardened front edge of the back ferrule can bite down and grip the softer metal of the tubing. This prevents an uneven transfer of torque and protects the system from leakages.

Functional Advantages of Using Back Ferrules

As noted, double ferrules are normally used when working with steel tube fittings to prevent an uneven transfer of torque. Therefore, tube fittings that use a back ferrule to grip the tubing incorporate better sealing technology than their single ferrule counterparts.

The back ferrule provides a double seal on stainless steel tube fittings, which creates an advanced and highly reliable seal. For this reason, double ferrules are the preferred choice for high-pressure applications such as a gas pipeline.

Conclusion

When working with tube fittings for any piping-based application, an appropriate and reliable seal between the various components is necessary to avoid leakages and subsequent damage. For stainless steel tube fittings, a back ferrule is used in conjunction with the standard ferrule to grip the tubing and provide a more advanced seal.