When to use Stainless Steel Pipe vs. Hose for Your Assembly

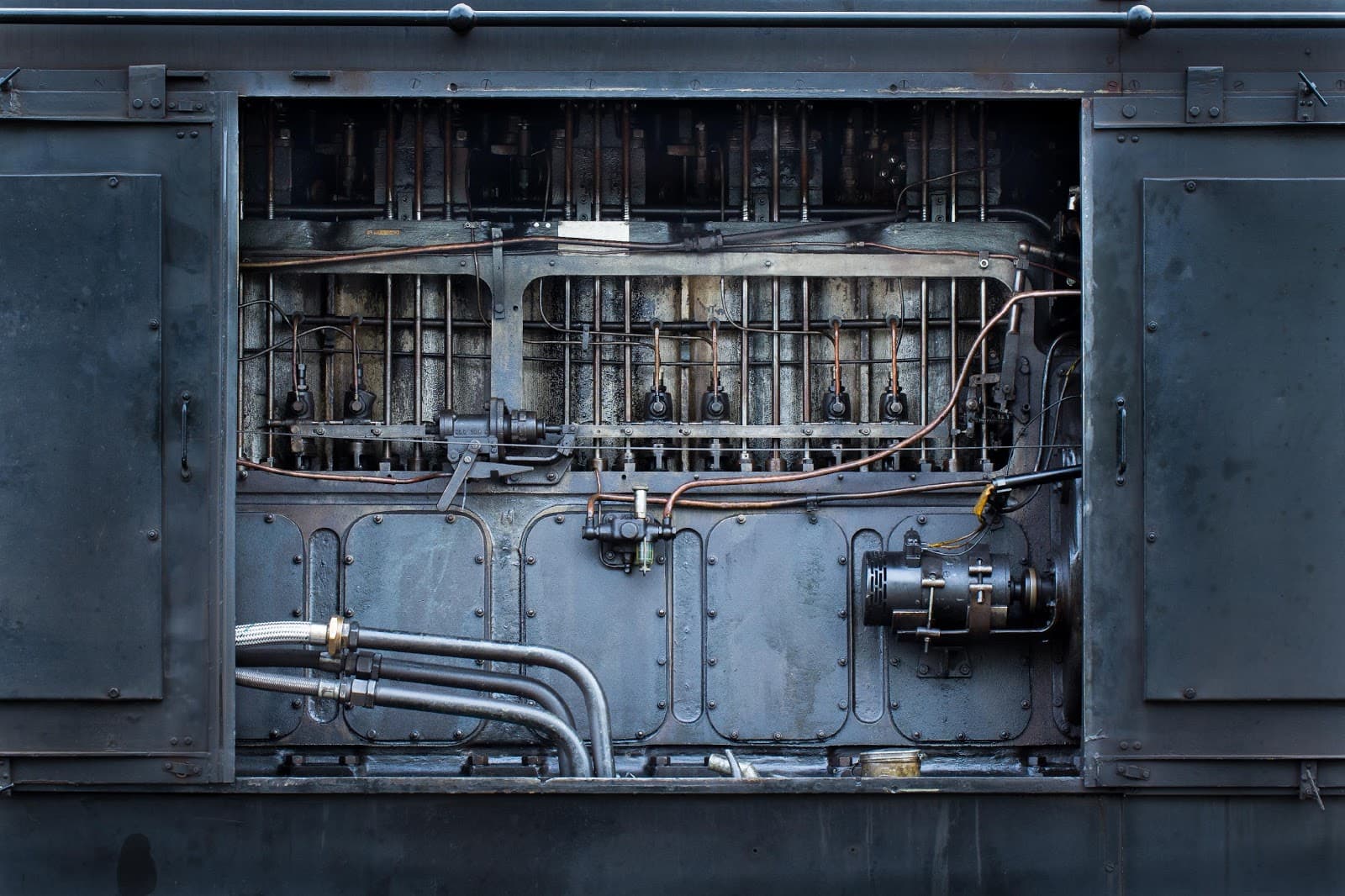

Image Description: An image showing a machine from the inside with different metal lines running to different components

When it comes to fluid conveyance in hydraulic systems, using stainless steel pipes and hydraulic hose assemblies are the most common choices. You’ll see many static and mobile hydraulic systems employing the use of both; however, it is rare to see one being used exclusively. There are a number of factors that go into designing a hydraulic system. Therefore, it becomes necessary to use one over the other. Here we explore the scenarios where stainless steel pipes are more suitable for installation in a hydraulic system over hose assemblies and vice versa.

Longevity

Most industrial systems are designed to remain operational for at least 30 years. Hence, they require components that can withstand the test of time. However, other factors also come into play when choosing the right material for your hydraulic lines. Even after you account for pressure and temperature for your system, vibration, abrasion, and corrosion still remain considerable factors that affect the longevity of a system.

In most cases, stainless steel outshines hydraulic hoses in terms of durability. Owing to its simple construction, resistant build material, and toughness, it can be readily used in small, high-pressure lines instead of hydraulic hoses.

Routing

Hydraulic components like pumps, filters, actuators, and valve bodies, regulate and convert the flow and pressure of the hydraulic fluid, converting them into useful work. Hence, a dense network of hydraulic lines is required to connect them with each other. You may be required to route different lines in a different manner, going through tight spots, leaving room for adjustment, considering expansion and contraction, and making sure no abrasions occur with other parts.

Hydraulic hoses are much more routing-friendly compared to stainless steel pipes. You don’t require special tools to bend them at certain angles; they’re simply flexible enough to connect at different points. However, hydraulic hoses cannot be bent as much as stainless steel pipes. So, for tighter radiuses, stainless steel pipes might be your only option.

Expansion

Hydraulic hoses are made of rubber with multiple layers for reinforcement and protection. When liquid passes through them at high pressure, they tend to expand and exhibit a decrease in length. This is particularly noticeable in lines that need to withstand sudden dips and surges in pressure. Excessive expansion leads to wear and also affects the fluid capacity of the line, impacting the response time. It is for this reason that most hydraulic systems requiring precision and accuracy, like robotic arms, require that stainless steel pipes be used for fluid conveyance. They exhibit extremely low to no expansion at all, making them an ideal component for the job.

Corrosion Resistance and Chemical Compatibility

There is no clear winner in this category as it depends on a number of factors. Whether you’re using stainless steel pipes or hydraulic hoses, you need to check whether the conveyance fluid is compatible with each or not. Additionally, it needs to be compatible with any peripheral components that the fluid comes into contact with, like O-ring inside fittings.

Assuming that both are fluid compatible, corrosion is a problem with stainless steel lines. However, it can be easily protected via a sacrificial coating or even paint. Hydraulic hoses are much more resistant to the external environment, but UV rays may damage their outer layer and degrade it over time.