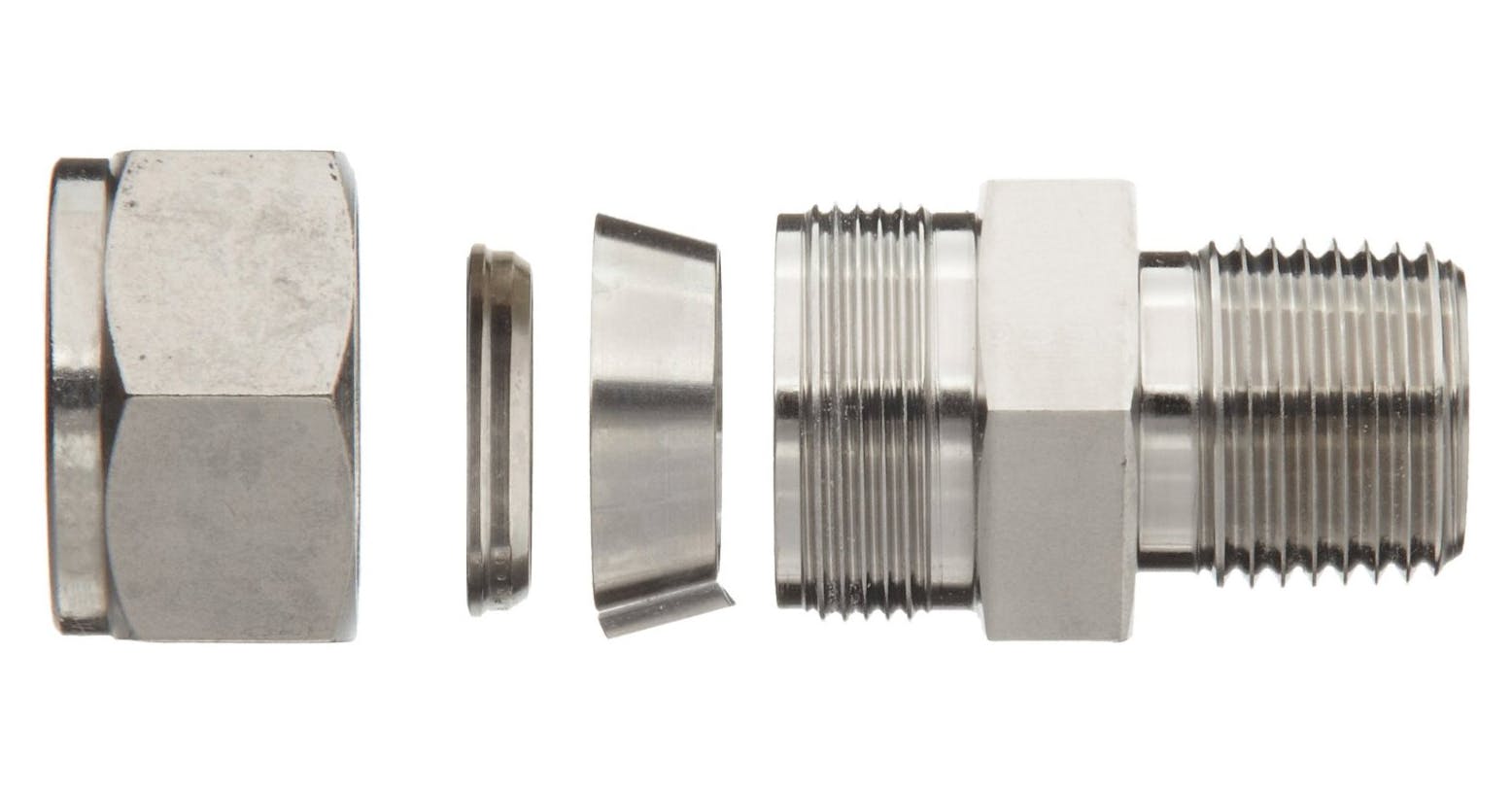

Image Description: Dual Ferrule Fitting

A ferrule is a small component used to seal a compression fitting assembly in piping and tubing-based systems. Such compression fittings are necessary elements in a large variety of tubing-based applications, from plumbing and gas lines to medical devices, chromatography, and inkjet printing.

However, since piping, tubing, and hydraulic systems are entirely manufactured from start to finish, they are always prone to failure. One of the most common sources of failure in a tubing-based system is the fitting or ferrule, the most common reason behind this being corrosion.

While single-ferrule components are also prone to failure, dual or twin ferrule components are much more likely to fail. This article will outline 3 common causes of back ferrule failures so that you know what to look out for next time your hydraulic or piping system shows signs of damage.

Incorrect Installation

Given that dual-ferrule fittings have been the hydraulics and piping industry standard for over 80 years now, they are highly likely to be compatible with most other fittings. The parts that make up the dual-ferrule fitting and its attachments are precision-engineered to create highly secure and leak-proof joints, especially for high pressure or high vibration applications.

That being said, dual ferrule fittings can be rather difficult to install properly. This can be because they are very small and can easily become lost, but it is mostly because there are about 20 different ways to install a dual-ferrule fitting, and only one method is correct. Installing the dual-ferrule incorrectly can lead to back ferrule failure.

Exposure to High Vibration

Part of what makes dual-ferrule fittings so effective is that the back ferrule grips the tubing from the inside and provides a highly secure leak-proof seal. However, for any tubing application that is subject to lots of vibration, it is necessary that the fitting be isolated from the vibration of the tube.

If you cannot meet this requirement in your tubing system, it could easily cause back ferrule failure. It is well known that the maximum destructive force caused by vibration occurs at the joint or support point of the system. Therefore, all the stress will concentrate at this single point in a vibrating system and easily cause back ferrule damage.

Additional Sealing Points

Many people abandon threaded pipes for their tubing system in favor of compression fittings, especially in a system that handles fluid or gas. This has the advantage of eliminating many potential paths for leakages. However, dual-ferrule compression fittings create additional sealing points in the system, introducing new leak paths in the system.

Hence, back ferrule failure could come about as a cause of these additional leak paths in your fluid or gas carrying tubing system.

Conclusion

When working with tube fittings for any piping-based application, an appropriate and reliable seal between the various components is necessary to avoid leakages and subsequent damage.

That being said, back ferrule failures have proven to be the most common cause of damage to a piping-based hydraulic system, with each of the three reasons above contributing to an equal number of such failures.