An Intro to Quick Connect Fittings and Their Uses

Quick Connect Fittings: Enhancing Efficiency in Hydraulic Systems

In the dynamic world of hydraulic systems, the efficiency and reliability of components are paramount. Among these, quick connect hydraulic fittings stand out as a pivotal innovation. These fittings are specially designed to facilitate rapid and secure connections in hydraulic lines, ensuring smooth operation and ease of maintenance. Let's delve into how these quick connect fittings operate, making them an essential component in hydraulic systems.

The Simple Mechanics Explained

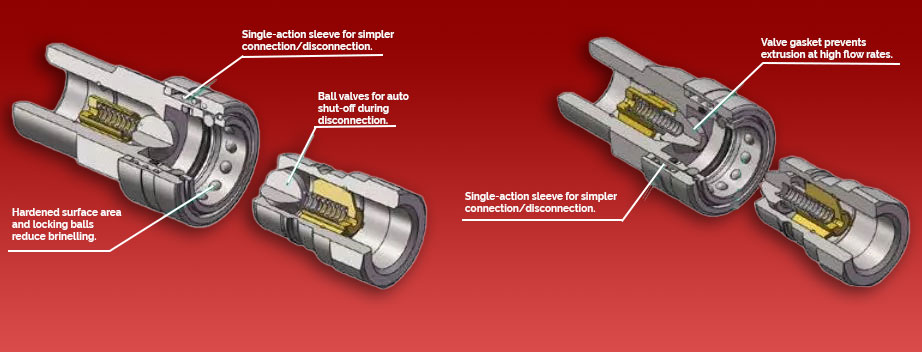

In hydraulic systems, the operation of quick connect fittings is ingeniously simple yet effective. These fittings consist of a male plug and a female coupler that are designed to lock together automatically when connected. This connection is typically achieved through a simple push-together motion, where the male end is inserted into the female coupler. Inside the coupler, there are locking mechanisms, often ball bearings or similar devices, that snap into place around the male plug, securing the connection firmly. This automatic locking ensures a tight seal, preventing fluid leaks and maintaining the integrity of the hydraulic system. To disconnect, a release mechanism, usually in the form of a ring or a button on the female coupler, is engaged. This action retracts the locking mechanism, allowing the male plug to be easily withdrawn. This quick connect and disconnect feature enables rapid assembly and disassembly of hydraulic lines, greatly reducing downtime during maintenance or system reconfiguration.

Materials Matter: Choosing the Right Quick Connect Fittings for Your Hydraulic System

Quick connect fittings for hydraulic systems are crafted from a variety of materials, each chosen for its unique properties and suitability for specific environments. Common materials include brass, which offers good corrosion resistance and conductivity; plastic, valued for its lightweight and cost-effectiveness, especially in less demanding applications; and stainless steel, which stands out for its exceptional strength and durability. Stainless quick connects are particularly favored for their excellent resistance to corrosion, making them ideal for use in harsh environments where they are exposed to corrosive fluids or extreme temperatures. This material also maintains its integrity under high-pressure conditions, a crucial factor in hydraulic systems. Furthermore, stainless steel fittings are known for their ability to resist wear and tear, ensuring a longer lifespan and consistent performance. This combination of durability, resistance to corrosion, and strength makes stainless steel an optimal choice for quick connect fittings in demanding hydraulic applications. The design of these fittings also varies, ranging from straightforward connectors to more complex shapes like elbows or tees, which cater to specific routing needs and space constraints within hydraulic systems.

Conclusion

In hydraulic systems, quick connect fittings are indispensable for their versatility, efficiency, and the safety they bring to fluid power applications. They enable quick changes and maintenance in hydraulic systems, ensuring minimal downtime and increased productivity. The ingenious design of these fittings allows for rapid, tool-free connections and disconnections, significantly reducing downtime and enhancing productivity in various industrial applications. Overall, the integration of quick connect fittings in hydraulic systems represents a significant advancement, ensuring reliable and effective fluid control in a variety of settings.

Frequently Asked Questions:

How do hydraulic quick couplers work?

Answer: Hydraulic quick couplers, essential for rapid connections in hydraulic systems, consist of two parts: a male plug and a female coupler, each with a normally-closed valve. To connect, the male plug is inserted into the female coupler, automatically opening both valves to allow fluid flow. A locking mechanism in the coupler secures the plug in place, with seals ensuring a leak-proof connection. Disconnection is achieved by engaging a release mechanism on the coupler, which frees the plug and simultaneously closes both valves, preventing fluid leakage. These couplers are ideal for applications requiring frequent, tool-free connection and disconnection of hydraulic lines, offering efficiency, reliability, and minimal fluid loss.

How to disconnect quick connect fittings?

Answer: To safely disconnect quick connect fittings, first locate the release mechanism on the female coupler, which may be a sleeve, button, or ring. Ensure the hydraulic system is depressurized before proceeding, as disconnecting under pressure can be hazardous and potentially damage the fittings. Engage the release mechanism by either pushing or pulling it, depending on the design. While maintaining pressure on the mechanism, gently but firmly pull the male plug away from the female coupler. Once disconnected, inspect both parts of the fitting for any signs of wear or damage, replacing them if necessary to guarantee a secure and leak-free connection in future use. Always adhere to the manufacturer's specific instructions for your particular fittings, as designs can vary.