The Art of Bending Stainless Steel Tubing

Bending Stainless Steel Tubing: A Guide for DIY Enthusiasts and Professionals

Bending stainless steel tubing – it might sound like a task reserved for the pros, but with the right know-how and a bit of elbow grease, it's something any DIY enthusiast or professional can master. In this comprehensive guide, we'll explore the art and science behind bending stainless steel tubing, covering everything from basic techniques to advanced strategies that can elevate your projects, whether they’re for your home workshop or a large-scale manufacturing operation.

Understanding the Basics: Why Bend Stainless Steel Tubing?

First things first, let's talk about why bending stainless steel tubing is a valuable skill. Stainless steel, known for its strength and resistance to corrosion, is a popular choice in various industries, from automotive to construction. Bending this material allows for creating custom shapes and angles, essential for bespoke designs and efficient piping systems.

Selecting the Right Tools for the Job

Choosing the right tool is half the battle won. For DIY projects, manual tube benders or hand-operated hydraulic benders are often sufficient. These tools offer simplicity and affordability. On the professional front, however, automated CNC benders provide precision and efficiency, especially for complex bends or high-volume tasks.

Preparation: The Key to Perfection

Before you start bending, preparation is crucial. Make sure your stainless steel tubing is clean and mark the bend points accurately. Lubrication is your friend here – it reduces friction and helps prevent kinks.

When it comes to bending stainless steel tubing in professional settings, there are several techniques used, each with its own set of tools, applications, and nuances. Let’s dive into some of the more prominent methods:

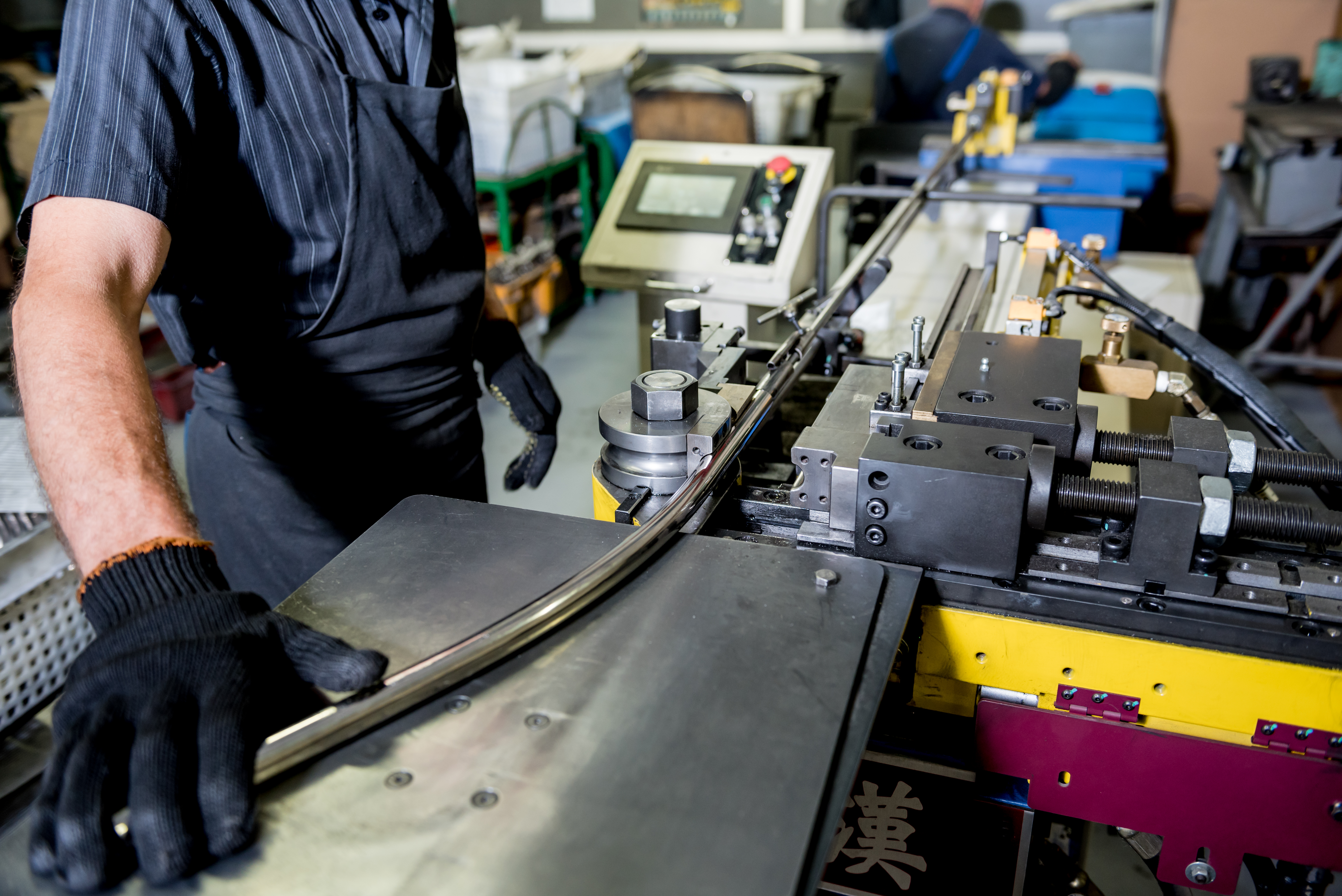

Rotary Draw Bending

Rotary draw bending involves a process where the tube is clamped and then drawn over a rotating bend die. This method relies on a clamp die to hold the tube in place, and a pressure die ensures it stays in contact with the bend die throughout the process. To prevent wrinkling, especially on the inside radius of the bend, a wiper die is often employed. This technique shines in scenarios where precise, tight radius bends are necessary. It's a popular choice in sectors like automotive for exhaust systems, in architectural designs for aesthetic elements, and for creating handrails with precision.

Mandrel Bending

Mandrel bending, a specialized version of rotary draw bending, involves inserting a mandrel – a solid metal rod or ball – inside the tube. This mandrel supports the tube internally, preventing it from collapsing or flattening during the bending process. Ideal for applications where maintaining a round cross-section is crucial, mandrel bending is widely used in industries like aerospace and automotive. It's particularly useful for bending thin-walled tubing where shape retention is key.

Press Bending

In press bending, the tube is pressed against two stationary dies to create the bend. Unlike rotary draw bending, it doesn't support the internal radius of the tube, which can sometimes lead to deformation. Press bending is often employed in scenarios where the internal shape of the tube isn't critical. It's a common method used in some structural applications and in the manufacture of commercial products where precision isn’t the highest priority.

Roll Bending

Roll bending utilizes a series of rollers to apply pressure and progressively change the tube's bend radius. The tube is passed through these rollers, which gradually shape it to the desired curvature. Suited for large radius bends, roll bending is a go-to method in the construction of cylindrical structures like tanks and boilers, and is also used in architectural applications for creating large, sweeping curves.

Heat Induction Bending

This technique involves heating a section of the tubing, which is then bent to the desired angle. The heat application makes the stainless steel more pliable, allowing for more substantial bends without risking cracks or weakening of the material.Heat induction bending is particularly useful in heavy industries like petrochemical, power generation, and oil and gas. It’s the method of choice for heavy-wall and tight-radius bends in piping where maintaining material integrity is essential.

CNC Bending

CNC (Computer Numerical Control) bending machines use precise and automated control to perform complex bending operations. The bending process is governed by computer programming, ensuring high precision and repeatability. In industries where precision is non-negotiable, like aerospace, automotive, and the production of complex industrial components, CNC bending is invaluable. It provides consistency and accuracy for intricate bending requirements.

Common Challenges and Solutions

Bending stainless steel tubing isn't without its challenges. Kinking is a common issue, often caused by bending too quickly or using an inappropriate die. Another problem is springback, where the steel tries to return to its original shape. Overbending slightly can compensate for this. Lastly, remember that not all stainless steel is created equal – different grades can behave differently when bent.

Safety First

Safety can't be overstressed. Always wear protective gear, including gloves and safety glasses. Ensure your tools are in good condition, and your workspace is clean and organized.

Bringing It All Together

So, there you have it – your guide to bending stainless steel tubing like a champ, whether you're doing it for a DIY project or in a professional setting. Remember, patience and practice are your best friends in mastering this skill.

FAQs

Can I bend stainless steel tubing without a specialized tool?

Answer: While specialized tools are recommended for best results, in a pinch, you can use a manual bending jig. However, this requires more effort and may not be as precise.

How do I prevent my tubing from collapsing during a bend?

Answer: Using a mandrel—a device inserted into the tube to support it during bending—can help prevent collapsing, especially for tight radius bends.

Can all grades of stainless steel be bent the same way?

Answer: Different grades have different properties. For instance, 304 stainless steel is more ductile than 316, thus easier to bend. Always check the properties of the grade you’re working with.