The Vital Role of Solenoid Valves in Brewing

Introduction

When it comes to brewing, each element of the process plays a significant role in determining the quality of the final product. Among these elements, solenoid valves hold a crucial position. These valves, often overlooked, are fundamental in managing the flow and quality of liquids throughout the brewing process.

Precision in Liquid Handling

Solenoid valves are essential for controlling the movement and flow rate of liquids in brewing. Their precision and reliability make them indispensable for various stages of the brewing process.

- Ingredient Flow Control: The accurate control of liquid ingredients is vital for consistency in taste and quality. Liquid solenoid valves precisely regulate the flow of water, wort, and other liquid ingredients, ensuring that each batch of brew meets the desired standards.

- Temperature Management: The brewing process requires precise temperature control during stages like mashing and fermentation. Solenoid valves are instrumental in managing the flow of hot and cold water, maintaining optimal temperatures throughout.

In the ever-evolving landscape of brewing technology, the drive for greater efficiency and consistency has led to significant advancements. At the heart of this progress lies the following:

- Automated Brewing Processes: The automation of brewing processes has been a game-changer in the industry. Solenoid valves are at the forefront of this revolution, enabling automated control over liquid flow, which leads to more efficient production and consistent quality.

- Reduction in Human Error: By automating liquid flow, these valves reduce the likelihood of errors that can occur in manual operations, ensuring a more reliable brewing process.

Selecting the Right Solenoid Valve

The selection of appropriate solenoid valves is critical for the specific requirements of a brewing operation.

- Flow Rate and Size: Choosing valves with the correct flow rate and size is essential for effective liquid management.

- Material Considerations: Opting for materials like stainless steel is crucial, given the corrosive nature of some brewing ingredients and the necessity for cleanliness and hygiene in the brewing process.

Conclusion

In the intricate craft of brewing, the significance of each component, no matter how small, cannot be underestimated. Solenoid valves, in particular, play a pivotal role in managing the flow and quality of liquids, directly influencing the efficiency, safety, and flavor consistency of the brewing process. For breweries looking to enhance their operations, focusing on the right solenoid valves is not just a technical decision—it's a commitment to excellence in brewing.

Frequently Asked Questions:

Can the use of solenoid valves impact the taste of the beer?

Answer: Yes, indirectly. By providing precise control over the flow and temperature of liquids, these valves ensure consistency in the brewing process, which is crucial for maintaining the intended flavor profile of the beer. Consistent temperatures and ingredient mixing lead to a more reliable and high-quality end product

What is a solenoid valve and how does it work in brewing?

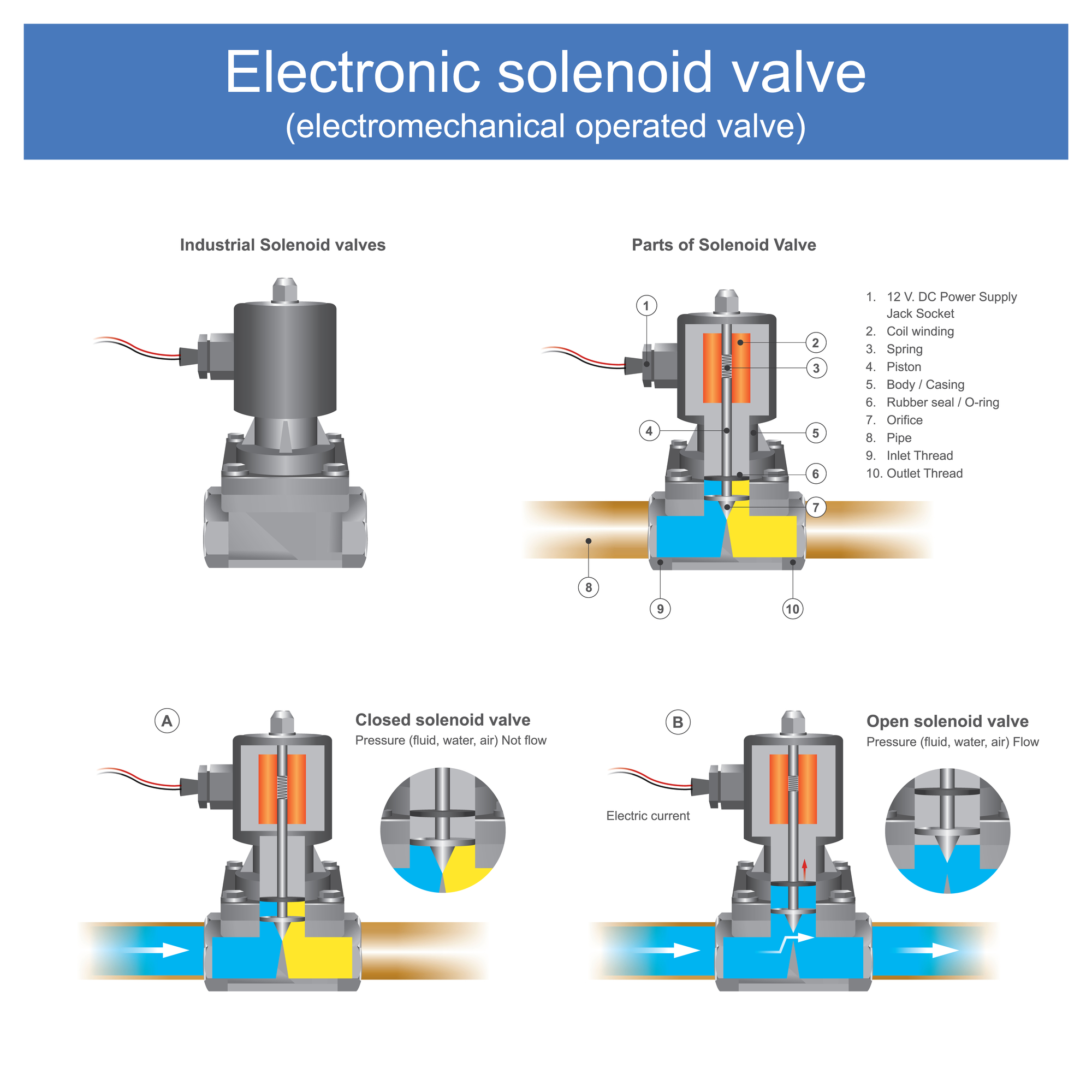

Answer: A solenoid valve is an electromechanically operated valve designed for controlling the flow of liquids. In brewing, it works by opening or closing in response to an electric current, which allows for precise control of liquid ingredients, such as water and wort, throughout different stages of the brewing process. This precision ensures consistency in flavor and quality in each batch of beer.