Understanding U Joints in Hydraulic Systems

Understanding U Joints in Hydraulic Systems

What is a U joint and how does it work?

A U joint, short for universal joint, is a mechanical joint used to connect two shafts that are not in a straight line. It consists of two U-shaped yokes and a cross-shaped center piece. As the shafts rotate, the U joint allows for flexibility and movement while maintaining constant power transmission.

What is a U joint and how does it work?

A U joint, short for universal joint, is a mechanical joint used to connect two shafts that are not in a straight line. It consists of a cross-shaped joint with bearings at each end and allows for the transmission of torque and rotation between the shafts while accommodating angular misalignment.

Hydraulic systems play a critical role in various industries, enabling machinery to perform complex tasks with precision and power. These systems rely on multiple components, where each part has its specific function and contributes to overall performance. One such component is the universal joint, or U joint, which is crucial for the efficient operation of hydraulic systems. In this blog, we will explore the basics of U joints, their functions, structures, maintenance tips, symptoms of joint failure, and what to do when U joints fail. So, let's dive into the world of U joints and gain a better understanding of their importance in hydraulic systems.

Diving into the Basics of Universal Joints

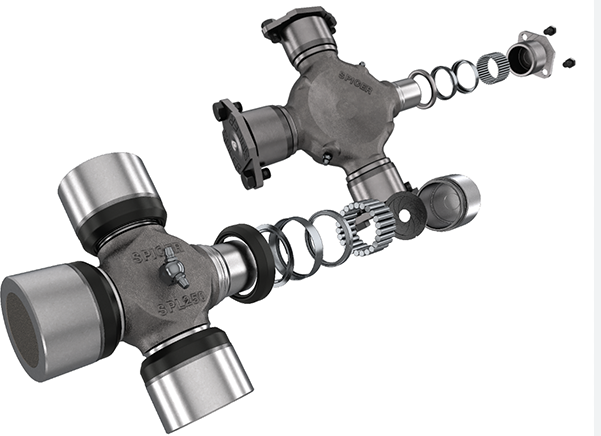

Universal joints, commonly referred to as U joints, are mechanical couplings used to connect two rotating shafts. In hydraulic systems, U joints are primarily used to connect the driveshaft of the machinery to the driveline, allowing for the transfer of power and torque. They consist of two bearing caps that hold bearings, surrounded by a yoke, which connects to the machinery's axle. This unique design allows the U joint to accommodate misalignment between the two shafts while still transmitting power. The bearings within the U joint enable smooth rotation, minimizing friction, and ensuring reliable transmission of power within the hydraulic system. The strength and durability of the bearing cap, axle, and bearings are critical for the U joint's optimal performance in hydraulic machinery.

The Function of U Joints in Hydraulic Systems

U joints play a fundamental role in hydraulic systems, facilitating the transfer of power from the driveshaft to the driveline. As hydraulic machinery operates, it generates forces, vibrations, and pressure changes. U joints allow for the accommodation of these movements, ensuring smooth power transmission and reducing stress on the machinery. The driveline, which connects the engine to the wheels or other moving parts, relies on the functionality of U joints to deliver power efficiently. In essence, U joints are essential components that enable hydraulic machinery to perform its intended functions accurately and seamlessly.

The Structure of U Joints

The structure of U joints consists of bearing caps, bearings, and an axle. The bearing caps hold the bearings, which allow for the rotational movement of the driveshaft. The axle connects the bearing caps and is responsible for transferring power from the driveshaft to the machinery's driveline. Bearings play a crucial role in minimizing friction and facilitating smooth rotation within the U joint. The design and construction of U joints focus on durability, longevity, and maintaining optimal performance, even under demanding operating conditions. This meticulous engineering ensures that U joints can withstand the forces, vibrations, and pressure changes experienced within hydraulic systems.

The Role of U Joints in Different Hydraulic System Sizes

Hydraulic systems come in various sizes, ranging from small-scale applications to large-scale machinery like Chevrolet vehicles. In both small and large-scale systems, U joints play a vital role in power transmission and driveline functionality. However, their design and application may differ based on the system size and specific requirements. Let's explore how U joints contribute to the optimal operation of hydraulic systems in different sizes, ensuring efficient power transfer, and enabling reliable performance.

U Joints in Small-Scale Hydraulic Systems

In small-scale hydraulic systems, such as those used in suspension systems, U joints provide the necessary power transmission and torque transfer. Due to their compact design, U joints can efficiently operate within limited spaces, allowing for seamless power transfer without compromising performance. Small-scale hydraulic systems, like those found in suspension systems, require reliable and compact components, making U joints indispensable for their functionality.

U Joints in Large-Scale Hydraulic Systems

Large-scale hydraulic systems, such as those used in heavy machinery like Chevrolet vehicles, demand robust and durable components. U joints designed for large-scale hydraulic systems are engineered to withstand the high forces, vibrations, and pressure fluctuations generated during operation. These U joints ensure the efficient transfer of power, enabling large-scale machinery to perform tasks effectively. The versatility of U joints allows them to adapt to the demanding requirements of large-scale hydraulic systems, contributing to their reliability and longevity.

Can You Operate the Hydraulic System without U Joints?

Operating a hydraulic system without properly functioning U joints is not advisable and can lead to severe driveline and suspension problems. U joints play a critical role in power transmission between the driveshaft and axle, allowing for the efficient transfer of torque. A faulty or absent U joint can disrupt this crucial connection, resulting in increased stress, vibration, and potential machinery damage. Attempting to operate the hydraulic system without functional U joints can have irreversible consequences, affecting driveline performance, suspension stability, and even compromising safety. It is essential to recognize the importance of U joints in maintaining the integrity and functionality of hydraulic systems.

Conclusion

To summarize, U joints play a crucial role in hydraulic systems by enabling the transmission of power between different components. They function as flexible connectors that allow for smooth movement and accommodate misalignment. The structure of U joints varies depending on the size and requirements of the hydraulic system, with different designs available for small-scale and large-scale systems.

Ultimately, U joints are integral to the operation of hydraulic systems and should not be overlooked. Proper understanding and maintenance of U joints can contribute to the longevity and efficiency of the system.