Why the Titan Hydraulic Hose is Equivalent to Similar Parker Hydraulic Hoses

Image Description: An image showing hydraulic components of a machine

When looking for hydraulic hoses, it is important to note the standards for the hose. You’ll find many standards on hydraulic hoses; however, the SAE J517 is most commonly employed by manufacturers to certify their quality and specifications.

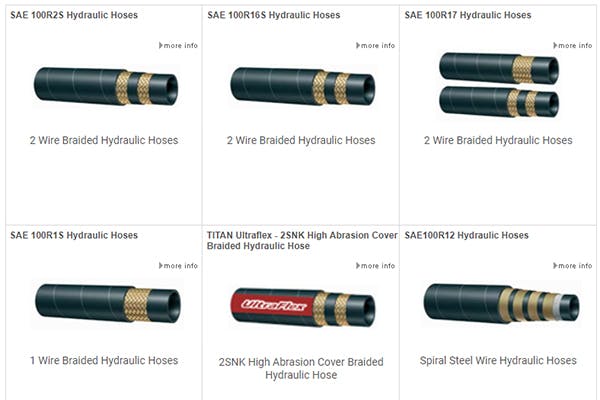

Most manufacturers don’t name their products in a way that reflects the standard. That’s not the case with Titan Hydraulic hoses. Not only do they mention the standard on their product’s name, but also which prominent manufacturer they’re interchangeable with, like Weatherhead, Aeroquip, and Parker. Below, we’ve compiled different types of hydraulic hoses from both Titan and Parker to give you an idea of their similarities.

Wire Braid Hydraulic Hose (up to 3000psi)

Based on the SAE 100R1 standard, Titan’s R1S hydraulic hoses are similar to Parker’s 422 (previously 421) series hydraulic hoses, with a single steel wire braid and synthetic rubber outer. Both allow for medium working pressures up to 3000 psi, with a fluid temperature between -40°F to 212°F.

Wire Braid Hydraulic Hose (up to 6000psi)

If you require higher working pressures of up to 6000 psi, then you’ll have to with Titan’s R2S hydraulic hoses. They have similar specifications to Parker’s 302 (previously 301 and BXX) series hydraulic hoses. Both are based on the SAE 100R2 standard with 2 braids of steel wire as reinforcement and a synthetic rubber outer cover.

Additionally, Titan’s R16S series and Parker’s 431/436 series double steel wire braided hydraulic hoses are based on the SAE 100R16 standard that allows for the same working pressures as the SAE 100R2 hoses but half the bend radius. Ideal for machinery with constricted spaces.

Spiral Steel Wire Hydraulic Hose

If your industry relies on heavy mobile equipment for its operations, then you must require spiral steel wire hoses to handle working pressures and sudden surges. Based on the SAE 10012 and SAE 10013 standards, Titan’s R12 and R13 series hydraulic hoses, respectively, are ideal for this application. Parker also produces similar hoses, like the 721 (SAE 100R12) and 781 (SAE 100R13) series.

Both products have at least 4 spiral steel wire layers for reinforcement with a tough rubber cover for added protection. All R13 hoses work at a high pressure of 5000 psi, while the R12 hoses can range from 2500-4000 psi.

Low-Pressure Hydraulic Hose

To keep your hydraulic system cost-effective, you won’t place high-pressure lines where they aren’t required. Hence, Titan provides low-pressure hydraulic hoses with 2 layers of synthetic textile braided reinforcement. This is similar to Parker’s 601 series hydraulic hoses as both are based on the SAE 100R3 standard. Perfect for low-pressure applications that go up to 1200 psi, like carrying fluid via return lines.

Final Thoughts

Standards allow us to keep track of hydraulic hoses, making engineers’ lives easier during maintenance regimes. If a hose requires replacement, it can be easily communicated to the procurement department by referring to its standard, ensuring that the new part comes with the correct specifications and is compatible with existing machinery.